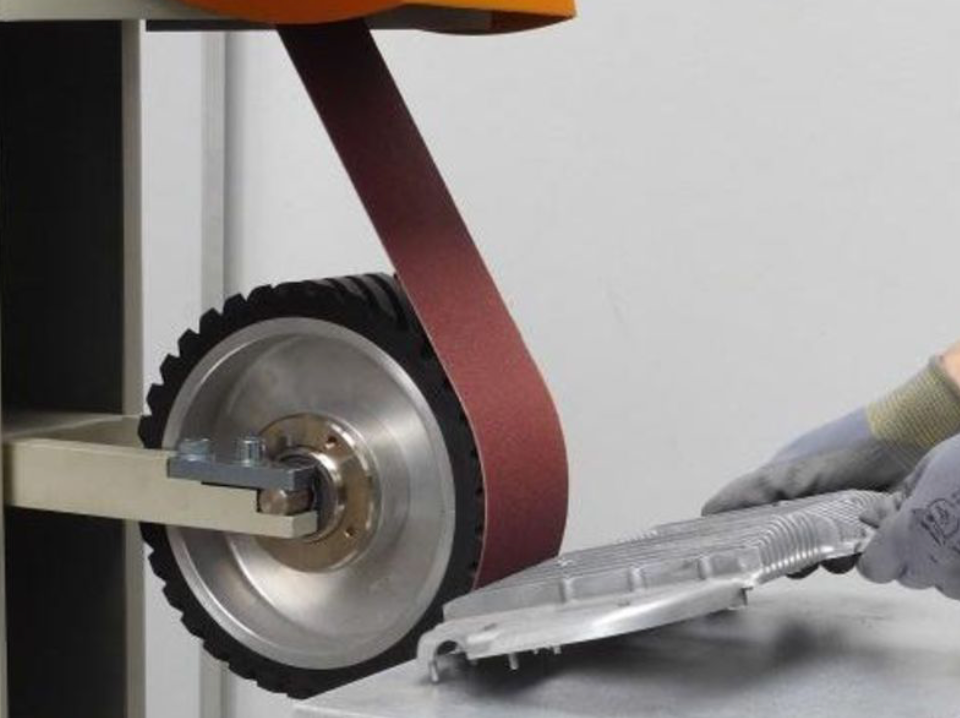

The widest range of electric and pneumatic linear action belt grinders, from light single hand belt grinders, mounted for use on stands or Robotics, through to rapid heavy stock removal with 2hp pneumatic motors. Numerous arm attachments operating belts widths 3mm to 50mm.

Please see our page "Hand held finishing tools by Seco Engineering"